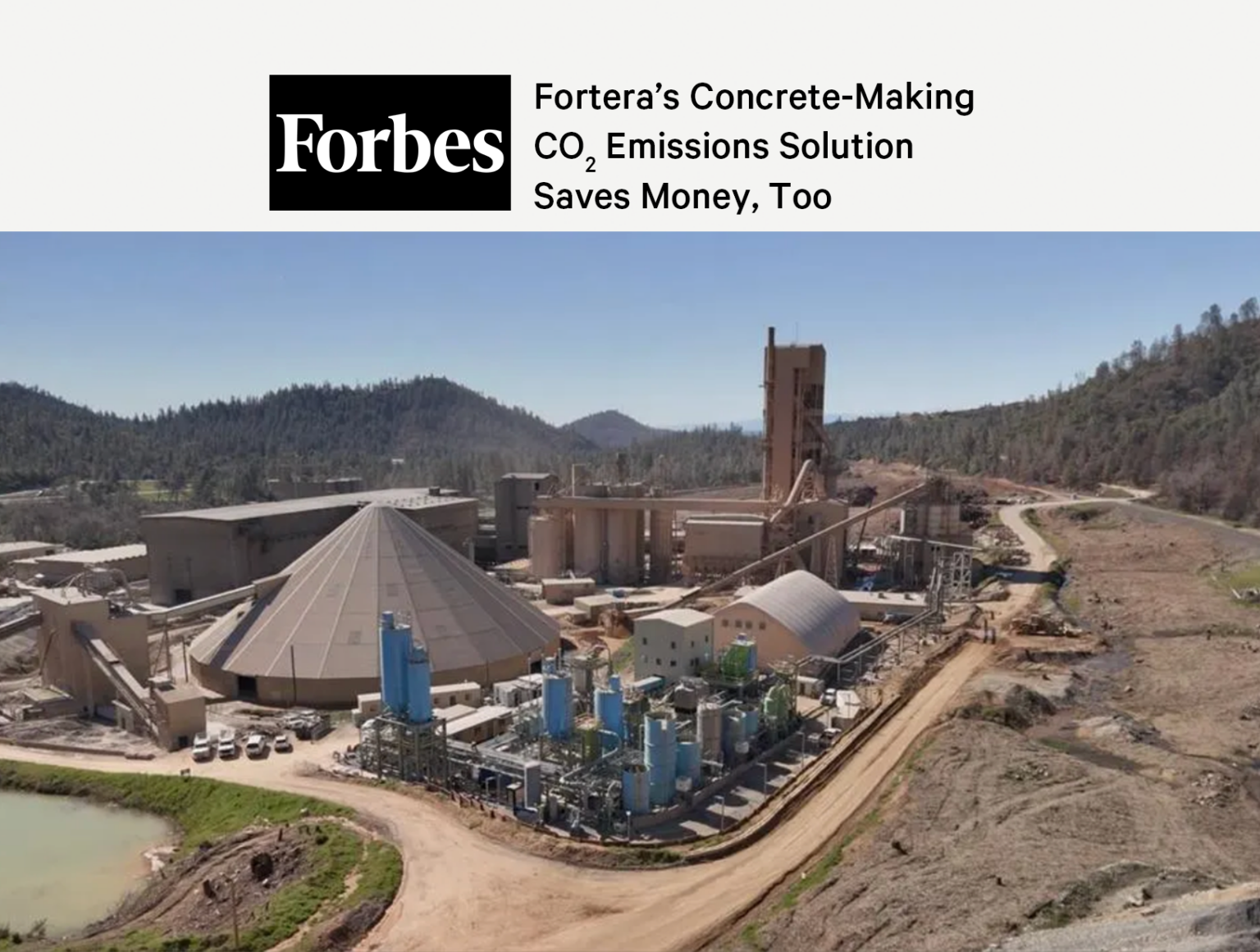

Fortera 2024 Year in Review

The year 2024 was packed with milestones as we delivered on our priorities across the business. We worked diligently and effectively to forge new partnerships in the cement and concrete industry. We made notable strides in commercializing low-CO2 cement, providing cost-competitive ways for customers to reduce their environmental impact while increasing strength and durability. We also fueled industry adoption of novel technologies and advanced our globally scalable vision by earning international regulatory approvals. Our achievements are the culmination of a strategy we call FIRE.